A mobile steam facility for sterilising substrate and soil was launched in the first quarter of 2016 at one of the largest national seed producers in Vietnam. The leading company is implementing the extremely cost-effective sandwich-type steam procedure for the first time using a hood with pins to sanitise topsoil up to a depth of 25cm under covered greenhouses, and thereby fully liberates them from weeds and soil-borne diseases.

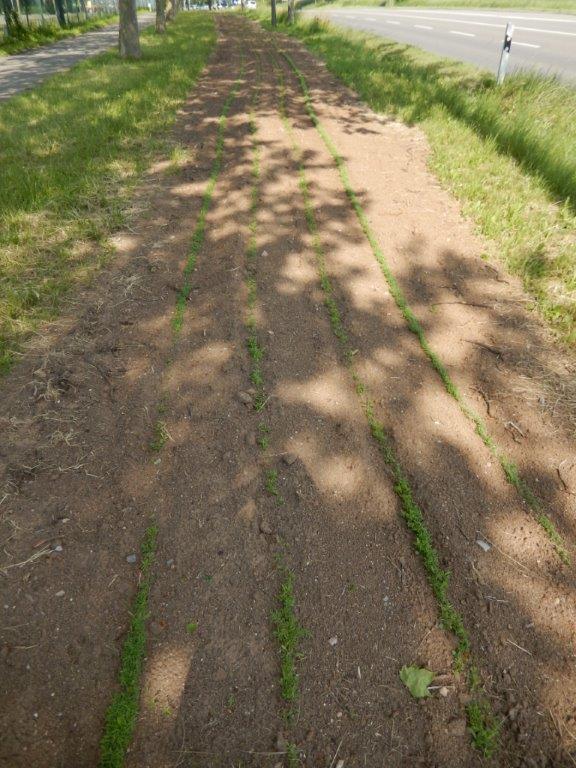

Here, two manually portable steaming hoods with a surface cover of 8m² and 20cm deep special hollow pins are applied in each case. Both hoods are used in parallel and alternately moved. A steam chamber with a steam output of 400kg per hour is therefore used. The system’s ground coverage amounts to up to 400m² per working day, in which the soil is heated to more than 80°C within seven minutes at a depth of 25cm.

In addition to steaming surfaces with the sandwich-type steaming method using a hood with pins, the company also sanitises large quantities of coco peat substrate. Therefore, special steam shelters were constructed with an extraction system and put into operation. Extraction is made possible using a special drainage system in the base of the individual immovable boxes. A mobile steam boiler, Type „S 350“, from the company MSD with a steam output of 400kg/h is also used for this purpose. The system works with the greatest efficiency and has the ability to fully clean up to 16m³ of coco peat at a target temperature of something above 80°C in one hour. The hot oil requirement rests on the basis of on-site readings with an average ~19L/h.