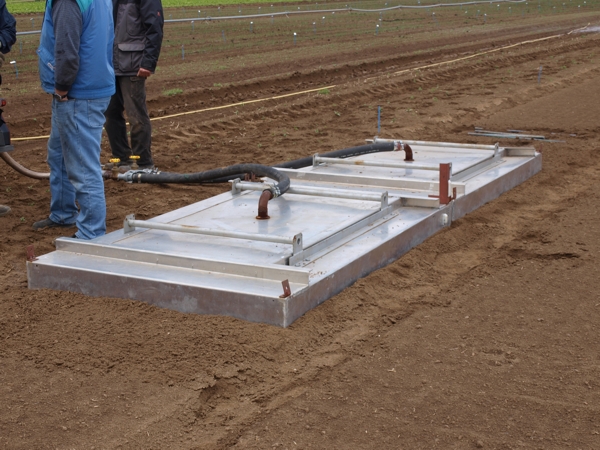

The MSD company has developed a new version of the steam mobile unit together with specialist machine manufacturer Josef Zeyer Agrarsysteme in Neresheim. The new edition came about subsequent to a direct enquiry from one our largest local producers of salad leaves. This new fully automatic steam machine sets new standards. In contrast to the previous model, which was produced by MSD Corp. in cooperation with the Swiss company Bärtschi-Fobro, this new field robot MSDZ-1 fulfils the latest requirements, in particular in the areas of approach area monitoring and tracking control.

In addition to the latest control technology, the steam efficiency of the system has been increased again by almost 40% on the previous model so that, under optimal conditions, surfaces of much more than 30 hectares can be completely freed of weeds annually.

The first new fully automatic steam machine is currently in test operation in areas in northern Germany in order to adjust it optimally to the current conditions. The machine will then be able to steam three rows of beds simultaneously, completely independently and without a driver, lifting, moving and then lowering the hoods again for this purpose until the end of the row of beds is reached. When the robot has reached the end of the row, it will send a signal indicating that it can now be moved by a driver. During the entire operation, however, the machine can also be operated via remote control.

Detailed information on price and performance of the new fully automatic steam machine can be obtained directly from the MSD company, especially online at www.msd-ag.de.

A video on Youtube can be watched here: VIDEO fully-automatic steam robot, 2016